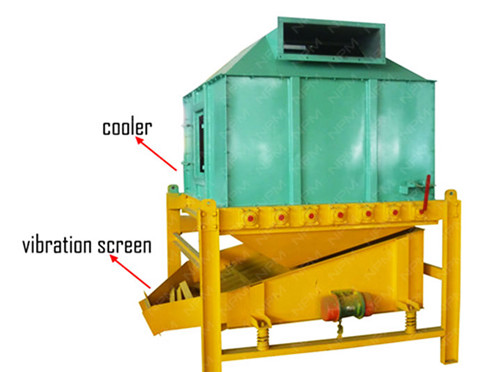

Why do you need a vibrating screen?

When making any biomass pellets, it is inevitable that after pelletizing, there will be powder material mixed with pellets. If you leave the powder material without doing any further processing, you may get the bagged pellets with powder gathered at the bottom which reduces the image and the quality of the appearance. ABC Machinery recommend you to try the vibrating screen to separate the powder out of the pellets and feed them in recycle, saving your material and earn more profit.

How does a vibrating screen work?

The motor is driving the screen to vibrate in different ways. The material that enters into the screen chamber is thrown upward and simultaneously moving forward. Due to the different size of meshes in different screen, the material is then fell onto different screen and is classified into different size and finally discharged from each outlet.

ABC Machiinery vibrating screen features in:

Full-locked structure, no dust float, no liquid leakage, no mesh block; Low energy consumption, simple structure, easy repair